Scuder Way Wipers supplies the complete range of products from the Loxeal Engineering Adhesives company, specialised in manufacturing a wide range of technically advanced Adhesives and Sealants. For more than 35 years, they have developed solutions for different industrial uses in machine tools (pastes, sealants, retainers, repairs, etc.).

We offer you a specific adhesive for each application:

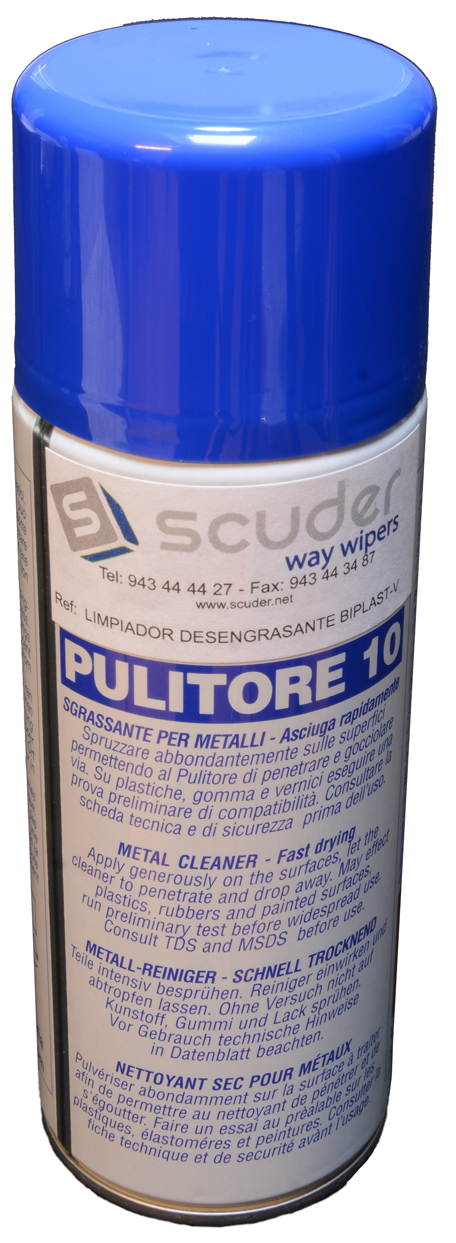

The cleaner LOXEAL Pulitore 10 is a mixture of free CFC solvents, particularly advisable for cleaning and de-greasing surfaces that are going to be adhered or sealed. Steel strips, Biplast-V® strips, etc.

De-greases and cleans surfaces. Provides for fast setting in cyanoacrylate adhesives under difficult conditions (large spaces, non-reactive materials), requires 1 to 4 seconds, depending on the type of adhesive

De-greases and cleans surfaces. Provides fast setting in a period between 20 seconds and 2 minutes, depending on the width of the assembly and room temperature. Apply the LOXEAL activator to one of the surfaces to be joined, and the adhesive or sealant to the other. Allow the solvent to evaporate before assembling parts. It can be used in both threaded and flat joints

Instantaneous super-quick ethyl cyanoacrylate adhesives. Low viscosity. Designed for rapid EPDM adhesion, foam rubber, rubbers with difficult adhesion, soft plastics.

(We recommend using it with the LOXEAL 9 Activator)

Instant ethyl cyanoacrylate adhesive. Average viscosity universal adhesive, able to adhere acid surfaces with fast polymerisation, even under low relative humidity conditions. Recommended for quickly adhering leather, wood, and metals.

(We recommend using it with Activator LOXEAL 9)

Anaerobic adhesive with average resistance for retaining bearings, bushings, and metal cylindrical elements intended to be disassembled with standard tools. It is resistant to high temperatures, abrupt changes in temperature, vibrations, oils, fuels, coolants, and other chemical products

(We recommend using it with Activator LOXEAL 11)

Anaerobic adhesive with high mechanical resistance and fast setting for fastening and sealing metal threading and to retain cylindrical metal elements. High resistance to temperature, thermal shocks, vibrations, chemical products, and ageing.

(We recommend using it with Activator LOXEAL 11)

Liquid Teflon.

Anaerobic adhesive, suitable for sealing threaded metal connections. Suitable for sealing gas, LPG, compressed air, oils, fuels, CFC, potable water, and other chemical products. Its low friction coefficient guarantees easy assembly, and its thixotropic properties prevent the product from migrating to the threading before and during setting. It replaces stow and PTFE tape. The hardened product forms a hard film with average resistance to disassembly. Resistant to impacts, vibrations, and thermal shock, and maintains its sealant properties in a temperature range spanning -55ºC/+150ºC, with peaks up to +230ºC.

(We recommend using it with the Activator LOXEAL 11)

Hydraulic sealant.

Anaerobic adhesive for average-resistance metals to seal hydraulic and pneumatic threaded connections. To seal gas, water, LPG, oils, hydrocarbons, and other chemical products. High resistance to temperature, rust, impacts, and vibrations.

(We recommend using it with Activator LOXEAL 11)

Anaerobic adhesive with average resistance to fasten screws and nuts of all kinds that may require disassembly. Suitable for use on lightly-oiled surfaces. High resistance to rust, vibration, water, gas, oils and fuels, and many chemical products. Tested resistance to loosening up to +200ºC.

(We recommend using it with Activator LOXEAL 11)

Transparent structural adhesive for general use and very fast setting for the structural joining of materials such as metal, ferrite, ceramic, marble, glass, concrete, wood, and some plastics (polyester, ABS, rigid PVC). Not recommended for rubber, soft materials, polyethylene, polypropylene and PTFE. Resistant to water, fuels, and oils.

Two-component adhesive (A+B), especially for difficult plastics. It provides an optimum result in a very short time period (10 min. approx.)

Superlox comes with a double manual 25 ml syringe with a mixing nozzle, meaning spray guns need not be used. The transparent colour is suitable for adhering transparent plastics.

Especially recommended for plastics that are difficult to adhere (polypropylene, polyethylene, HDPE, LDPE, PTFE, plexiglass, ABS, PVC) and is also useful for adhering other materials such as metal, wood, etc.

Structural adhesive for self-levelling fillers, transparent, for general use in structural joining of many materials: metal, ferrite, ceramic, marble, glass, concrete, wood, and some plastics (polyester, ABS, rigid PVC). Not recommended for rubber, soft materials, polyethylene, polypropylene and PTFE. Resistant to water, fuels, and oils.

Tenacious two-component epoxy resin, formulated to join different kinds of materials: composites, metals, ceramics, ferrite. Particularly recommended for electro-mechanical assemblies.

Its mixing process is approximately 30-40 minutes, and it sets in 24 hours at room temperature.

It has very good resistance to impact. It has good resistance to water, oil, and gasoline.

Thixotropic two-component epoxy resin, hardened, which hardens in cold and moderate temperatures. Formulated to join metal, ceramic, wood, expanding substances, and a great number of plastic materials.

It has good resistance to hydrocarbons and oils, and its slow setting provides for possible repositioning of parts and joining large surfaces. It provides tenacious adhesion, with high resistance to blows, impacts and vibrations. Its high viscosity provides for filling large spaces and vertical applications.

Two-component contact-setting adhesive, drop-by-drop, thread-by-thread, does not require thorough mixing. Handling time is 1 to 3 minutes. Recommended for adhering metal, ceramic, glass, wood, and some hard plastics. It provides joints with high resistance to impacts, stripping, and traction.

Neutral silicone sealant adhesive with low odour, ideal for sealing telescopic defences, protective bellows, gear boxes, gears, breakers, flanges in pumps and motors, oil and water containers, and compressed air tubes. It polymerises with a reaction to atmospheric moisture, forming an extremely flexible joint between surfaces of different materials (metal, plastic, glass, ceramic, etc.). Resistant to vibrations, thermal shocks, pressurised air, water, oils, and other chemical products. The seal remains unalterable at a temperature range of -50º and +180°C. Sealed parts may be disassembled, using normal tools.